{Available only in the full enterprise version}

This page will be activated if you'll enable the "Log activity" box on the previous page.

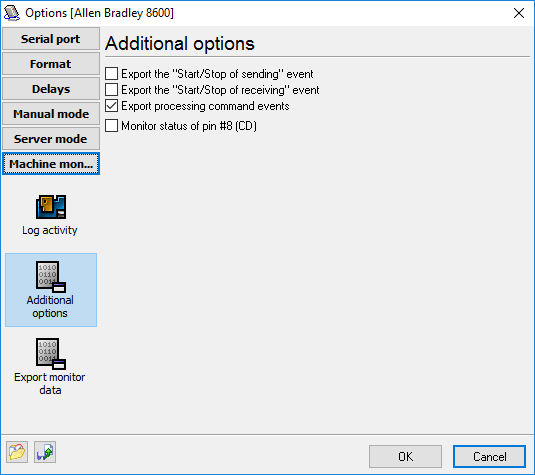

Fig. 16. Additional options.

Export "Start/Stop sending" event - the program will write a text message to a log file when the program starts and stops sending a program to a machine in the server mode. It can help you to track an operator activity.

Export "Start/Stop receiving" event - the program will write a text message to a log file when the program starts and stops receiving a program to a machine in the server mode. It can help you to track an operator activity.

Monitor status of pin #8 (CD) - You can use a small relay and connect it to the signal that powers the "in cycle" light bulb or LED on the operator's panel. This relay then turns on one of the unused handshake lines on the RS232 cable (say, pin #8, or CD). Our DNC software just watches this signal, and knows the CNC is in cycle if it's on, and out of cycle when it's off and writes a corresponding row to a log file.

•Debounce intervals - this interval can help you to remove non-significant events that can generate a relay. 0 - don't use a debounce interval.

•Invert CD signal - it depends on your relay connection schematic.

•Ignore CD signal while sending data - some machine turn "In cycle" signal off when receiving data over RS232 interface. In this case, this option can help you exclude non-significant events.