What is Data Acqusition? - What is Data Acqusition? Where is a place of our Data Logger in a data acqusition system?Trust In Confidence! For Windows 2000 - Windows 11 (2022) (incl. Server, x86 and x64). Latest version: 4.7.7 build 417. April 17, 2024. Data acquisition is the process of sampling signals that measure real-world physical conditions and converting the resulting samples into digital numeric values that can be manipulated by a computer. Data acquisition systems (abbreviated with the acronym DAS or DAQ) typically aggregate data from multiple different data sources to one system (database, control system, content management system, billing system, etc.). In the modern world, DAQ systems get data from intelligent sensors that convert analog signals to digital form and output data through communication interfaces. The components of data acquisition systems include:

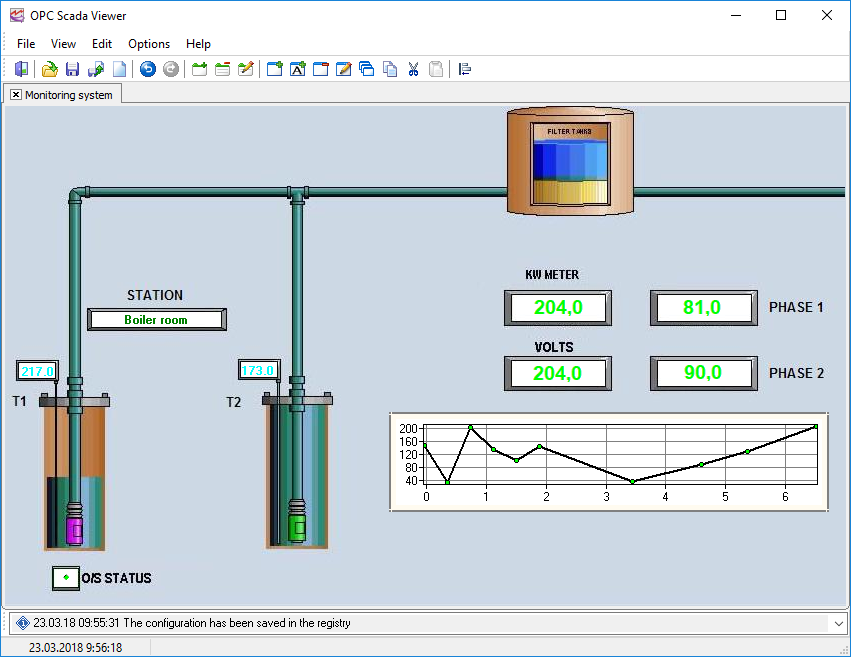

Software programs control data acquisition applications. Our Data Loggers can be used as a bridge or gateway between data acquisition hardware (sensors, controllers, IoT, etc.) and a high-level management or graphing system. Our software can work on all modern Windows OS. CommunicationsCommunication features include fast serial data transfers at up to 921,200 baud. The software supports any number of remote devices and up to 255 wireless links. Hardwired network operation (up to 255 loggers per network) is also supported. Or you may decide to use our Data Logger Suite software that allows you to collect data from a network, OPC, DDE, and many other data sources to one place. GraphingUsually, data is viewed in the high-level system. Also, SCADA systems are widely used in data acquisition systems. Suppose it is too complicated in your case. In that case, we can offer to draw charts in Excel or use our OPC Scada Viewer utility where data channels can be combined into a single viewport or separated as desired. The user can select various indicators, modify colors, fonts, and other display options. GlossaryRS232 - A standard for serial communications found in many data acquisition systems. RS232 is the most common serial communication. However, it is somewhat limited in that it only supports communication to one device connected to the bus at a time, and it only supports transmission distances up to 10 meters. RS485 - A standard for serial communications found in many data acquisition systems. RS485 is not as popular as RS232. However, it is more flexible in that it supports communication to more than one device on the bus at a time and supports transmission distances of approximately 2500 meters. The Industrial Ethernet IO systems can be used for data acquisition, machine monitoring and process control. Either as a stand-alone system or controlled from a remote computer, data can be acquired, processed, stored and shared over the network. Advanced Serial Data Logger related topics:Serial port interface RS232 port logger Com port logger RS232 data logger Data Logger Software For Electricity Meter RS232 to ODBC RS232 to MySQL RS232 to MS SQL Server RS232 to database |

|

| Copyright © 1999-2024, AGG Software. All rights reserved. Terms of use | Privacy policy |