{Available only in the full enterprise version}

The Machine monitor function in DNC Precision utilizes the Fanuc Macro-B functions to passively monitor "Cycle start", "Cycle stop", "Tool change" and other events that your machine can generate. The following describes how to set it up.

If you have "User Macro B" in your Fanuc control, you can use the POPEN, DPRNT, and PCLOS statements. Not all Fanuc have this option, however, so we use another method as well. On any Fanuc control, if you go to EDIT mode and type: POPEN then press INSERT, the CNCs that have the option will display the word just like it's shown. If it puts spaces between each letter, like this:

P O P E N

then the CNC doesn't recognize the POPEN key word, and you don't have the option.

Insert a Macro Call Command at the beginning of the NC Program, right after the ‘O<number>’, and another Macro Call Command at the end, just before 'M30’. These quite simple macros utilize the DPRNT declaration to transmit a short character string from the serial port of the CNC. At the beginning of all NC programs, insert this Macro Call:

O9010 (CYCLE START MACRO)

POPEN

DPRNT[(***CYCLESTART***)]

PCLOS

M99

O9010 (CYCLE STOP MACRO)

POPEN

DPRNT[(***CYCLESTOP***)]

PCLOS

M99

If you use certain O-numbers for these macros, you can also assign a custom G-code or a custom M-code to automatically call them. In some cases, you won't even need to modify your programs at all. For example, if all your programs have a certain G-code at the beginning (say, "G20" for Inch programming), you can just put the number "20" in a parameter to make "G20" always call macro 9010. Similarly, you can have the control call the "CYCLESTOP" macro with the M30. The parameter locations for these settings are different in each model Fanuc control, so you will have to look them up in the manual.

On the DNC side, just keep the port open and listen for the word "CYCLESTART" or "CYCLESTOP" (followed by a Line-Feed) then record the event in a file with the Date and Time variables from the PCs internal clock. You can then go back later and analyze all these events and calculate how many cycles you have, average cycle time, average load time, etc. We even tie this into our automatic paging and e-mail software, so someone can get a page or e-mail if the machine has been idle for more than (x) minutes.

For machines that DON'T have User Macro B, you can try another method for cycle start/stop monitoring:

You can use a small relay and connect it to the signal that powers the "in cycle" light bulb or LED on the operator's panel. This relay then turns on one of the unused handshake lines on the RS232 cable (say, pin #8, or CD). Our DNC software just watches this signal, and knows the CNC is in cycle if it's on, and out of cycle when it's off. In this case, you can't use activity triggers and can use cycle start/stop monitoring only. You can enable this feature on the "Additional options" tab.

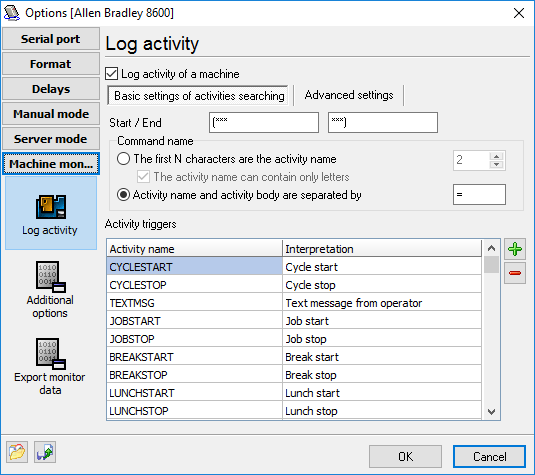

Fig. 15. NC activity triggers.

Basic and advanced settings are very similar with same settings of the server mode. Here, you can define rules, that our software will use to extract your activities. Please note that you should use another format of activities if you are using the server mode because your activity trigger names can interfere with NC commands in the server mode.

Default values are:

Activity start: (***

Activity end: ***)

So, your activity will be (***A=1234***) or a program with activity within:

O9010 (CYCLE STOP MACRO)

POPEN

DPRNT[(***A=1234***)]

PCLOS

M99

It is an example only, and you can define your own rules and activity triggers. You can use many built-in trigger names and their interpretations, or define a new one. For example, you can define a trigger with name "A" and interpretation "Smoking" and the program will export this text to a log file.

So, you defined activity triggers. If you didn't define a trigger name, then the trigger with this name will not be exported.

The list of activity triggers is not limited by cycle start/stop commands. You can define few macro or call DPRINT within your main program. Some examples are listed below:

When a spindle start command (M03 or M04) is executed, this macro is called:

O9xxxx

POPEN

DPRNT[TOOLCHANGE=#4120[40]]

PCLOS

M99

The DNC software will write this activity and tool number to a log file.

When a spindle stop command (M05) is executed, this macro is called:

O9xxxx

POPEN

DPRNT[TEXTMSG=Punch beginning]

PCLOS

M99

The DNC software will write your custom message to a log file.